Education

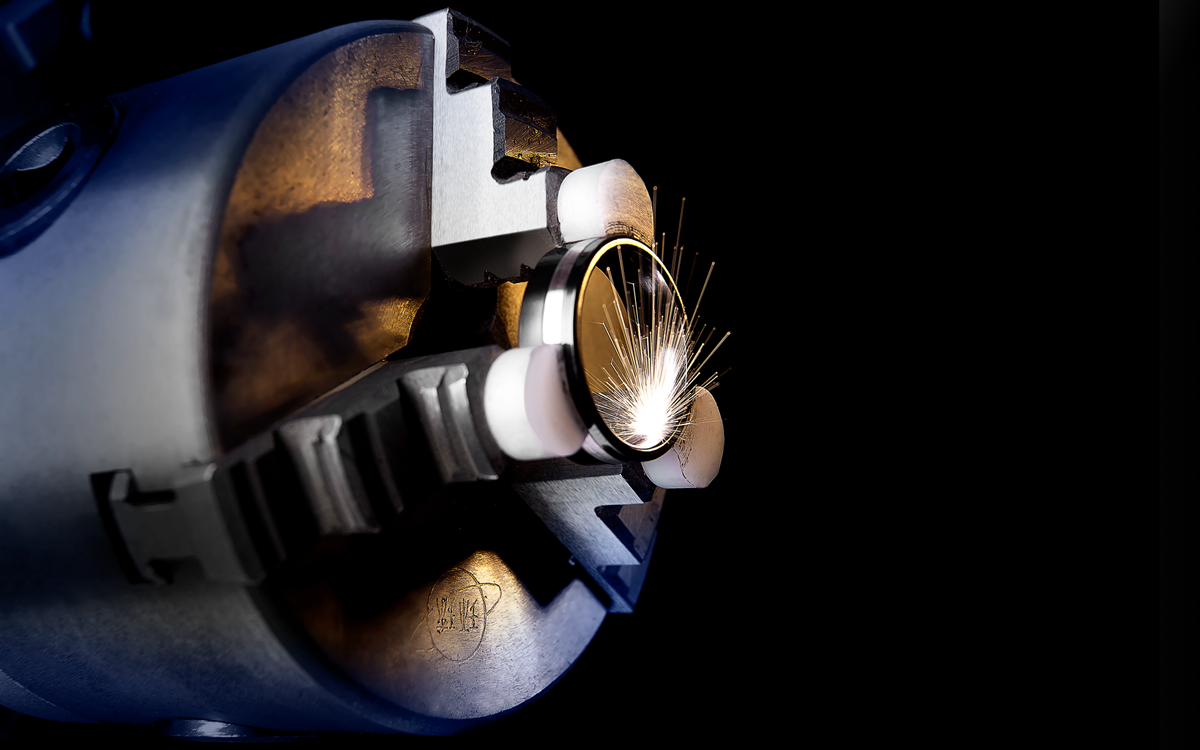

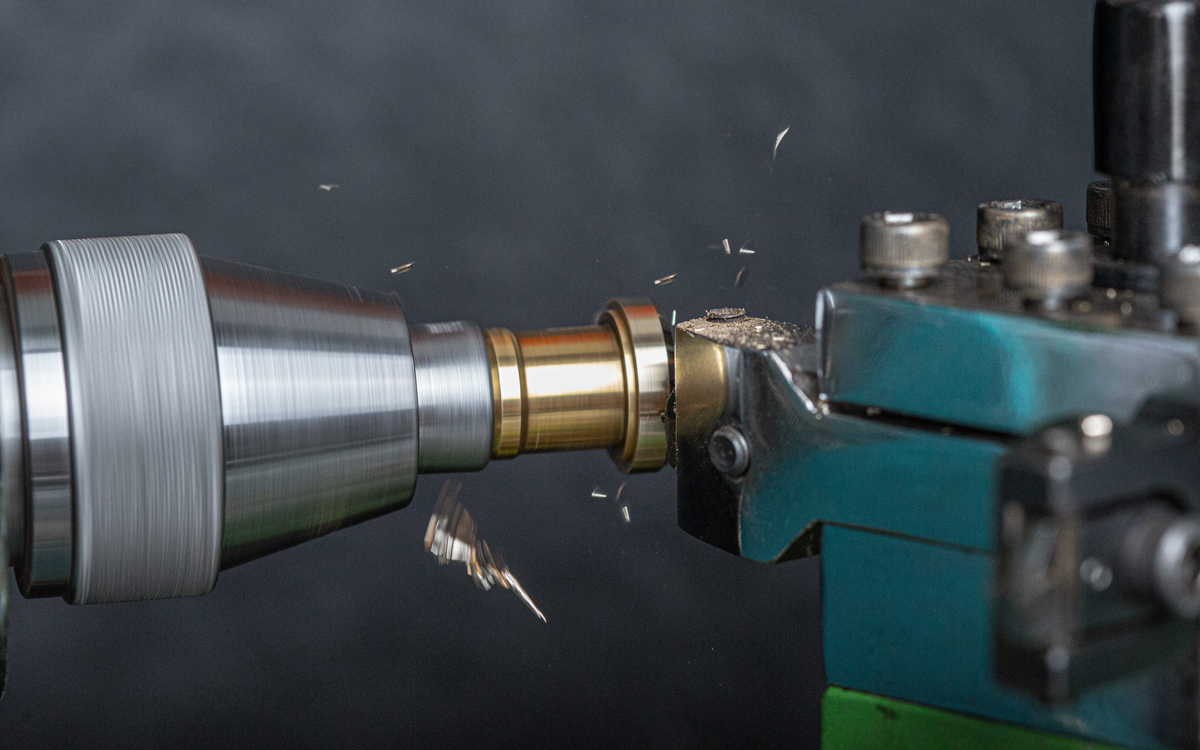

CNC (Computerized Numerical Control) milling machines use rotary cutting tools to carve a jewelry model from a blank of gold or platinum. The programming process generates a code which controls the machine to produce the desired product. The number of axes in the machine can vary, three to eleven-axis the most common in the industry to produce zero a porosity jewelry product. According to the functions or types of machined parts, CNC machines can be classified into five types: CNC milling machines, CNC lathes, CNC drilling machines, CNC plasma cutters, and CNC grinders.

Traditional jewelry casting is done through the lost wax process, whereby models created through wax carving, growing, or printing are encased in a plaster - like medium known as investment. Investment is heated to extreme temperatures to burn the material, creating an impression of the desired form. The burned cavity is then filled with melted precious metal.

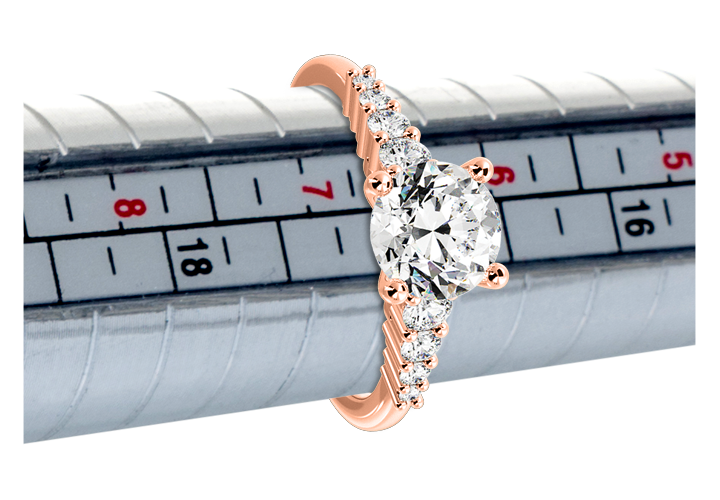

Getting the right finger size is the most important factor for Traditional Wedding Bands.

- All Kozza & Company rings are sized above the marker line.

- All Womens’ Wedding Bands are available in sizes 4 to 9.

- All Mens’ Wedding Bands are available in sizes 4 to 14.

- 1/2 and 1/4 sizes are available upon request

- Wider rings tend to fit tighter. Therefore, please consider allowances to prevent any discomfort.

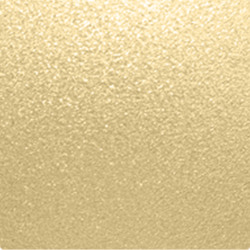

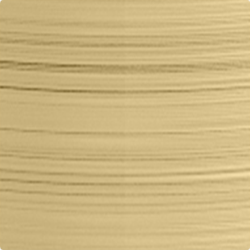

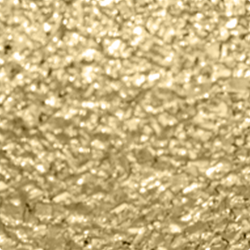

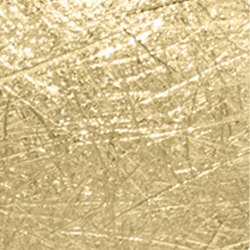

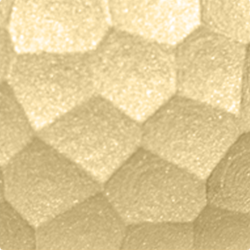

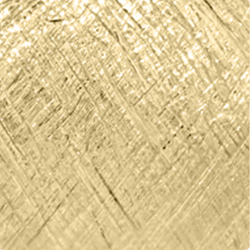

We offer all finish options illustrated below for most of our Traditional Wedding Bands. Available finish options for each individual model are also illustrated next to those models displayed in this catalog. For any special requests, please inquire with our Customer Service. All images for the finish options in this catalog are for illustrative purposes only, actual results may differ slightly.